Quality, transparency and trust are the core values that drive us at Precot to deliver sustainable cotton products. We are committed to building a long-term partnership based on trust with all our clients.

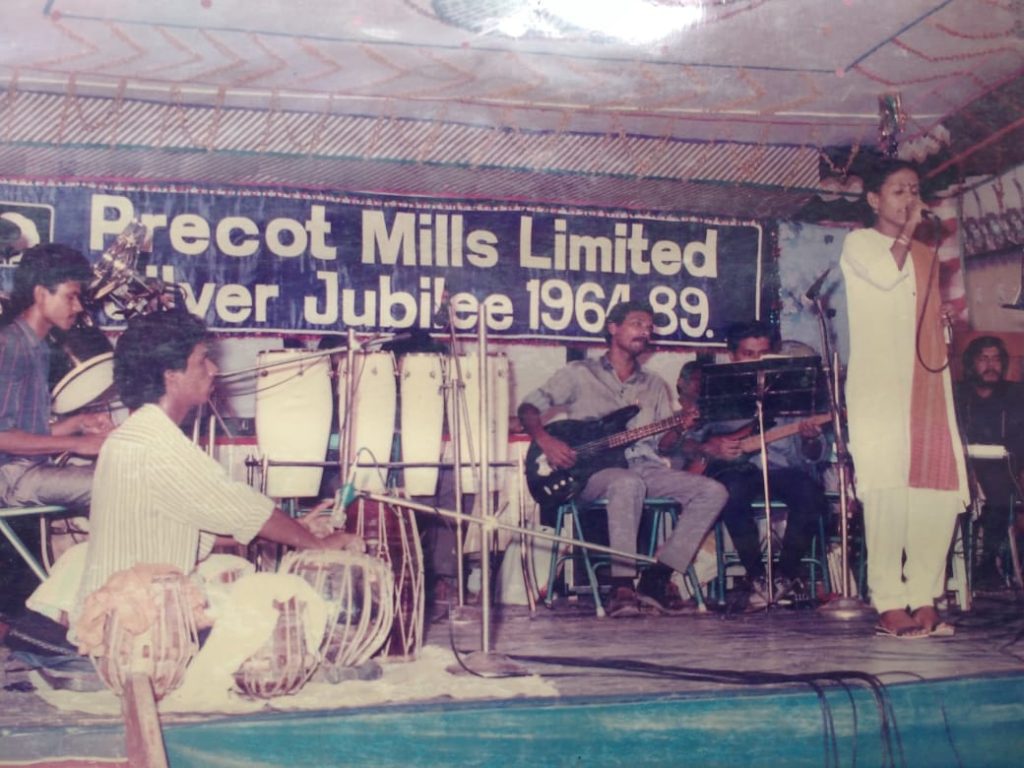

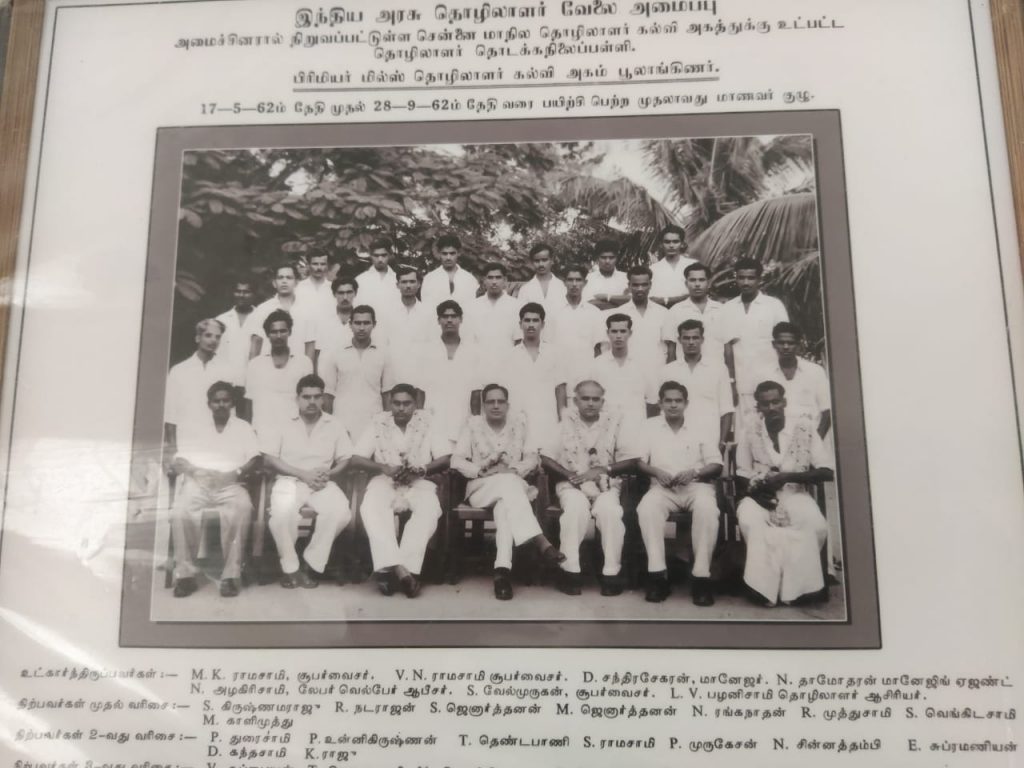

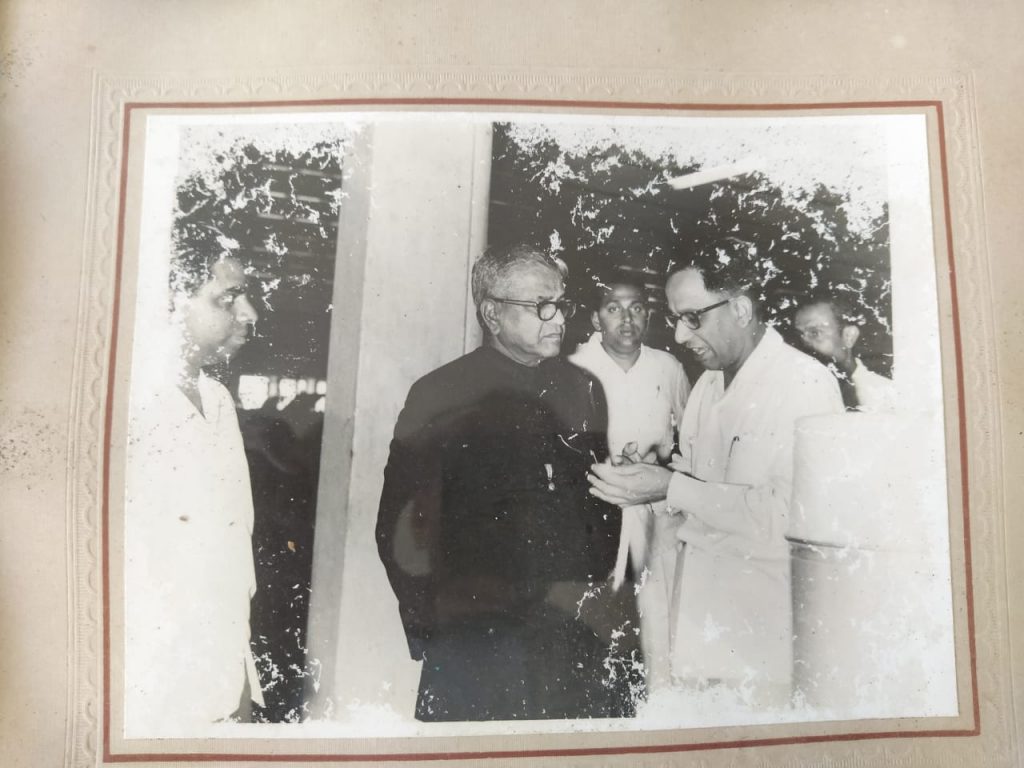

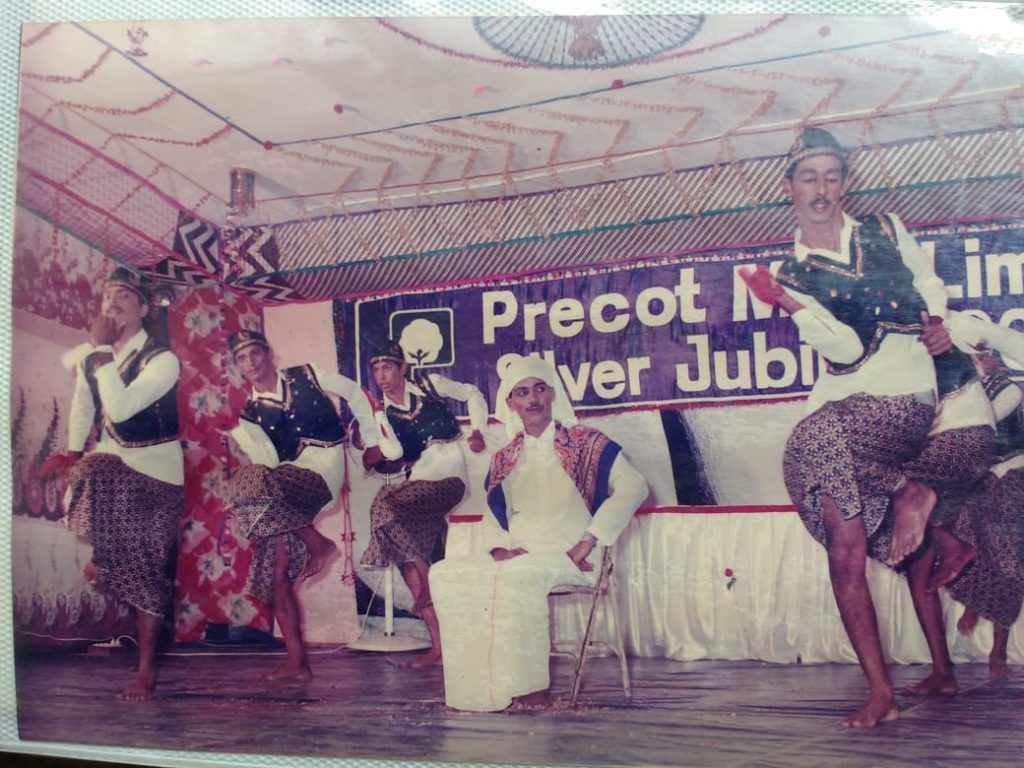

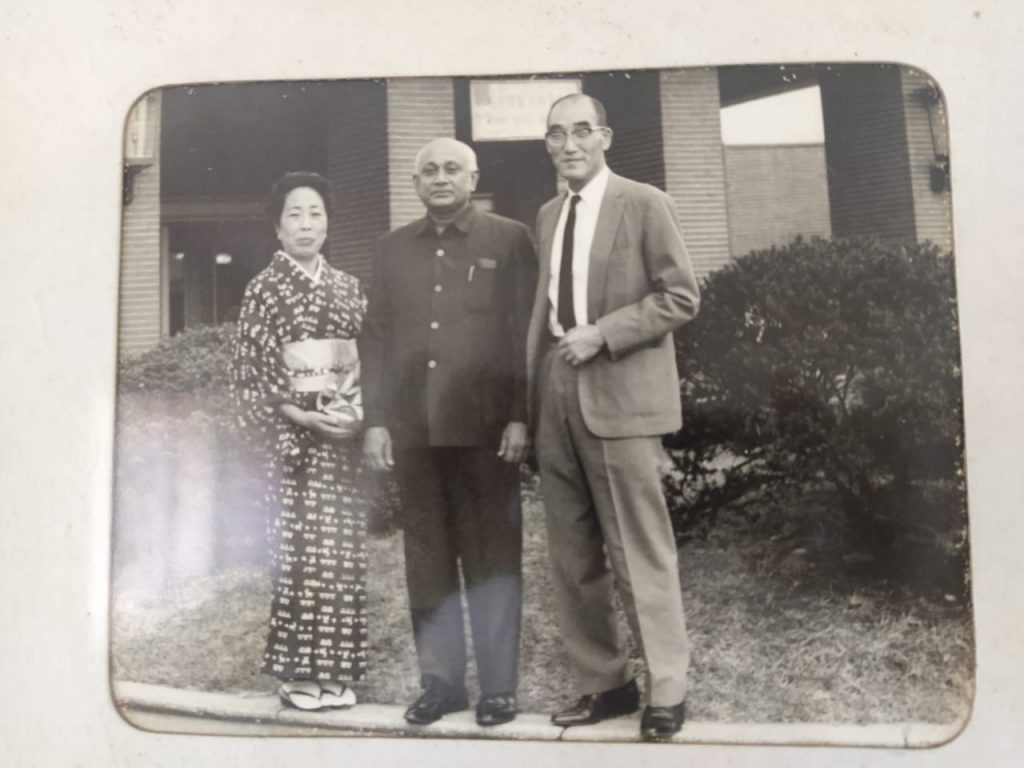

Around 60 Years in the Cotton Industry

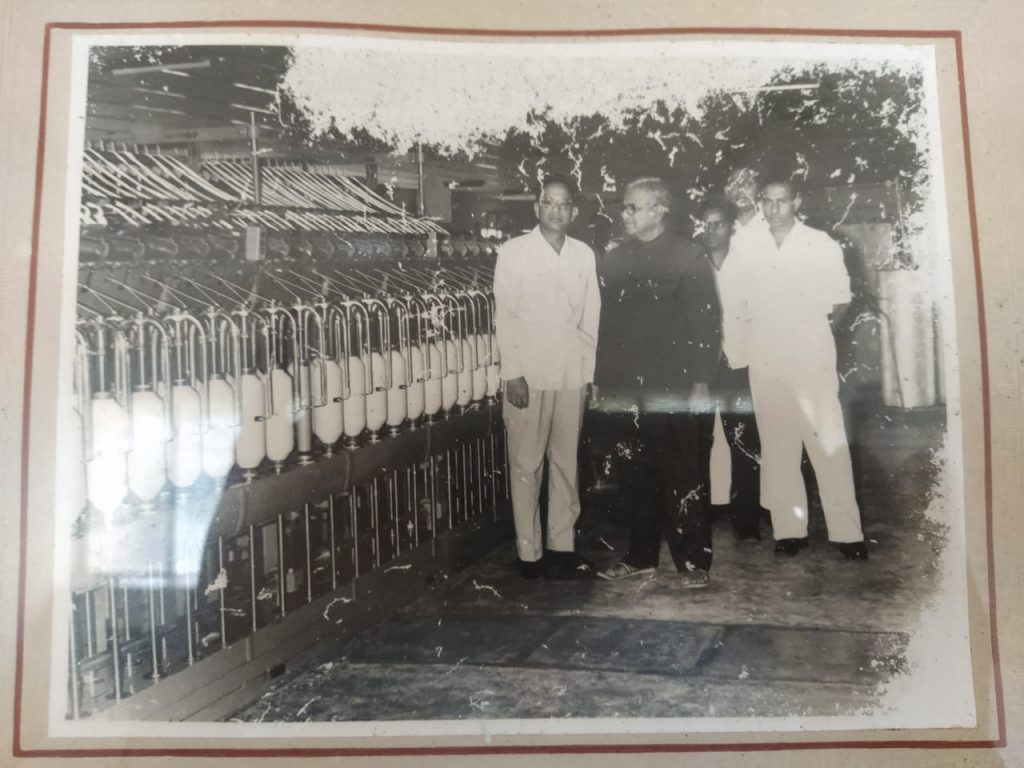

When we started production in 1962, we had an initial capacity of 12,096 spindles. Our first cotton mill was in Kanjikode, Kerala. Now, we have units in Tamil Nadu, Kerala, Andhra Pradesh and Karnataka. We have 188112 spindles. This journey has taken us 6 decades and along the way, we’ve grown as an enterprise and a brand. We gradually adopted sustainable practises, starting from growing organic cotton to using green energy. We are proud to be one of the leading cotton mills in India with an international presence. Precot is one of India’s top suppliers of cotton products to textile mills, manufacturers and brands.

Vertically Integrated Facility

Our vertical integrated facility places us at a strategic advantage in terms of production efficiency and quality output. This system allows us to fine tune our supply chain so that we are able to quickly distribute supplies when the demand increases. It gives us more control over the supply chain, from production to delivery. At the same time, it helps lower prices, which is beneficial for our customers.

Cleaning & Peroxide Bleaching

- Fiber Opening

- Hydro-Entanglement

- Pad Punching as per Customer Request

- Finished Product Manufacturing

Packaging

Shipment

Sustainability

Sustainability is one of the core principles on which our entire business process is built. From sourcing to packaging, we follow sustainable practises every step of the way. It is because we believe that our success is not just in the profit margins, but also in what we return to the environment and the people who work with us.

We also aim to raise awareness about sustainable cotton products, so the mills, manufacturers and brands that partner with us also use organic cotton. This way, we can soon make organic cotton a mainstream choice across all segments. By increasing use of sustainable cottons, we help the cotton farms, their farming ecosystem and their communities.

At Precot, we follow sustainable practices in three major areas – Sourcing (Raw Material), use of green energy and eco-friendly waste management system.

Compliance and Quality Standards

Precot is an ISO 9001 and 14001 certified company that meets the BCI standards for cotton industry. We have an integrated quality management system to evaluate the quality of the product at every step of the production process. We are also:

- Certified for SA – 8000 requirements

- Certified for BRC standards

- Certified for OEKOTEX

- GMP & FDA certified

Our production and quality systems adhere to REACH guidelines and are within international pharmacopoeia limits. To evaluate quality adherence, we have state-of-the-art testing laboratories with quality check instruments such as DATACOLOR, USTER and PREMIER. Tensomax and Uster evenness tester are used to measure single yarn strength. We also follow 3M methods to reduce resource wastage.

Innovation

We are continuously looking for innovative and sustainable solutions in cotton manufacturing.

- Product innovation – patented product (exfoliating pads)

- Packaging innovation – design & sustainability

Whether it’s the use of advanced technology or high-end equipment, we have an open-mind approach cleaning and spinning, we use innovative methods to get higher quality products. We understand the needs and demands of our clients, both manufacturers and retailers to deliver tailored products. Trace back the life of your product right from the point of origin using our traceability methods. We have an in-house research and development and value engineering team that works towards identifying novel solutions and designing products that meet the diverse market demands.